TEC was developed through the manufacturing process of soluble silver clusters, as opposed to the existing conductive ink that disperses nano particles. When the metal (Ag) is dissolved in solvent, it appears to be a clear liquid without particles, but after printing and heat treatment process, a high-density silver layer with superior conductivity is formed.

It is clear with no concept of particles (sub-nano), has excellent stability, and enables low-temperature sintering and thin film materialization to be applied in various areas of the electronic parts material industry.

InkTec’s Materials for Printed Electronics

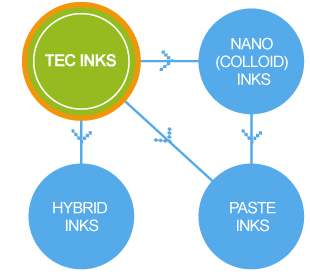

Based on InkTec’s own TEC ink, InkTec has been developing and supplying various materials with specialized printing methods and applicable products, and with decades of accumulated technical skills, we are capable of free viscosity control and optimum response to customers’ needs. The materials currently manufactured and distributed by InkTec are in the forms of Ag Cluster Complex based on TEC Ink. There’s also the paste form using nano dispersion and nano powder and flakes, and a hybrid form using Ag complex and Nano/Flake, which are applied in diverse printing processes, such as inkjet, screen, spray, and roll to roll-based printing (Gravure, Flexo, gravure offset, etc.) They are also used for functional purposes (optical products / decoration) in addition to general electrodes.

Conductive Paste / inkmore information

Product Class |

Process method |

Material type |

Main components |

Applicables |

PA series |

Flat screen, imprinting, |

Conductive paste |

Ag powder |

TSP Bezel, Health care, |

LT series |

Screen printing after exposure & devolopment |

Conductive paste |

Ag powder |

Passive component |

LD series |

Screen printing after exposure & development |

Dielectric, Insulation paste |

Ceramic powder |

Passive element |

DP series |

Dipping |

Conductive paste |

Ag nanopowder |

Passive element |

Co series |

Coating(Spray/ Spin, etc) |

Ink |

Silver ion complex |

Mirror effect |

IJ series |

Inkjet (Aerosol, Electrostatic, etc) |

Ink |

Silver ion complex |

General electrode |

PR series |

Gravure, Flexo, Slot die |

Ink |

Ag nanopowder |

General electrodes |

EMI series |

Dispensing nozzle |

Ink |

Ag nanopowder |

Semiconductor and EMI Shielding |

Conductive Ag nanopaticle

Product Class |

Particle size |

Material type |

Ag concentration (wt%) |

Application |

NP20 |

≒ 20nm |

Wet cake |

85 ~ 90 |

Low temperature sintering type, Higt electrical conductivity, Thermal conductivity , Electrode material for flexible printing electronics |

NP20D (Dispersion) |

≒ 20nm |

Disperse emulsion |

40 ~ 80 |

Same as NP20 |

※Contact : E-mail ei@inktec.com TEL +82-31-490-6422